Choosing the right materials is critical at beachside

Salt is the ultimate paradox.

On the one hand used to preserve food such as meat before the advent of refrigeration, conversely it is bane of the construction industry due to it severe corrosive effect on many building materials.

Landmark Products has built hundreds of outdoor structures around Australia located either directly on the beach or nearby, and is well versed in designing and building for maximum life-span in these areas. Considering Australia’s 19,000 km coastline, it’s an important skill.

Many products are simply not appropriate for coastal conditions, for example, untreated exposed steel. Other materials have “marine grade” versions available, which are products that have been created specifically to be used on or by the sea.

So, when it comes to building public infrastructure in high salt locations, what should be considered to ensure the longest life-span possible.

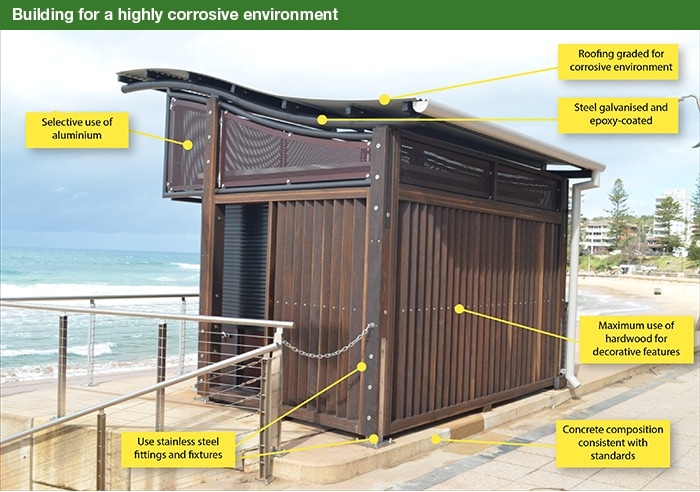

Timber. When building near the beach, use as much timber as possible, particularly hardwood, which has been treated and/or stained. If you are considering decorative cladding or aesthetic features, timber is your best option.

The latest timber-look composite products such as Modwood is also a good option. These products are salt, heat and water resistant, and without the same tendency to expand and contract, require much less maintenance.

Aluminium. Though not completely infallible, aluminium is one of the metals most resistant to corrosion due to its ability to spontaneously form a thin but effective oxide layer.

Although without the same structural strength as steel or hardwood, aluminium should be considered as an option wherever possible, for example, for hand rails or panelling.

Steel. On most occasions, the use of steel within a structure is unavoidable. Although, steel has the capacity to be extremely susceptible to the elements, there are plenty of options to increase its lifespan. All steel used near beach or high salt environments should be galvanised and epoxy-coated, such as with two-pack or plas-coated.

Inground rather than bolt-down. When it comes to anchoring structures to concrete slabs, in-ground is the best option in corrosive environments, as it protects metal brackets and fixtures from the air, within the concrete.

Bolt-down inevitable means greater exposure of metal base plates and hardware to the environment. Overtime, water and moisture can become trapped between the slab and base plates, increasing the risk of corrosion.

Stainless steel. Stainless steel resists corrosion better than most other metals because of a very thin, colourless passive layer that forms spontaneously on the surface. When the passive layer is breached, it usually forms again spontaneously.

In aggressive environments, such as very close to the beach, the passive layer may be unable to form, and some corrosion may take place. Although the stainless steel may look ‘tea stained, it will corrode more slowly than most other metals, and will remain serviceable long after any other common engineering metal.

In addition, 316-grade stainless steel is recommended for all fixtures (except roof screws).

Roofing. There are metal roofing options available that have been specifically developed for salt or salt spray environments. Suppliers recommend which grade of roofing is applicable depending on how far a structure is from the breaking surf or calm marine.

Concrete. Concrete too can be adversely affected by salt-rich environments. For this reason, the consistency and strength of concrete, whether for slabs or footings, is determined by a number of variables, including the distance from breaking surf, whether the structure is above or below the Tropic of Capricorn, and the size of the footing or slab.

Maintenance. In the case of all building materials, the more often the maintenance such as washing down with fresh water, the longer the structure will last.

There are also considerations regarding electrical fit-outs, plumbing and various fitting and fixtures when building in high salt areas, and Landmark Products Project Consultants are ready to assist our potential customers to understand the factors involved.